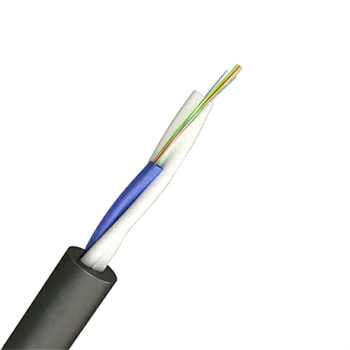

Anti-Rodent Double Jacket Non-metalic cable

Anti-Rodent Double Jacket Non-metalic fiber optic cable for aerial installation

2. Structure Description

1 | Central strength member (CSM): GFRP rod |

2 | Fiber288F IUT-T G652D |

3 | Loose tube containing fibers and filled with a suitable water tightness filling compound |

4 | Loose tubes SZ stranded around CSM |

5 | Core filling compound |

6 | Water blocking tape |

7 | Anti-rodent glass yarn |

8 | Outer Sheath: Black MDPE |

10 | All materials are RoHS compliant |

3. Part No.:

NTOFC-GYFTY53-L-HDPE-BK-SMD-C

1 2 3 4 5 6 7

1,Catalogue | 2,Cable Model | 3,Cable structure | 4,Jacket Material | 5,Jacket Color | 6,Fiber type | 7,Fiber count |

OFC:Optical Fiber Cable | GYFTY63 | L:loosen tube | HDPE | BK:Black

| SMD:G652D

| 12-288 |

4. Specification:

Parameter | Values | ||||||||||||||

Fiber Count | 12 | 24 | 48 | 72 | 96 | 144 | 288 | ||||||||

Loose tube | Counts | 2 | 4 | 4 | 6 | 8 | 12 | 24 | |||||||

Diameter(mm) | 1.8 | 1.8 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | ||||||||

Thickness(mm) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

Material | PBT | ||||||||||||||

Water Blocking | Tube filling compund | ||||||||||||||

Fiber Counts per tube | 6 | 6 | 12 | 12 | 12 | 12 | 12 | ||||||||

Central strength member | Material | FRP | |||||||||||||

Size/mm | 1.4 | 1.4 | 1.6 | 2.2 | 2.1 | 2.1 | 2.1 | ||||||||

Anti-rodent yarn | Material | Anti-rodent glass yarn | |||||||||||||

Outer Sheath | Material | FR Flame-retardant HDPE,black | |||||||||||||

NomThickness(mm) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | ||||||||

Overal diameter(nom.)(mm)(±0.2) | 10.4 | 10.4 | 11.2 | 11.7 | 12.7 | 15.7 | 17.8 | ||||||||

Cable Weight/kg | 85 | 85 | 85 | 100 | 122 | 180 | 240 | ||||||||

Tension Strength IEC60794-1-2-E1 | Short Term(N) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | |||||||

Long Term(N) | 600 | 600 | 600 | 600 | 600 | 600 | 600 | ||||||||

Crush Resistance(N/100mm) IEC60794-1-2-E3 | Short Term | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |||||||

Long Term | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | ||||||||

Min.Bending Radius(mm) | Static | 15D( D is the cable diameter) | |||||||||||||

Dynamic | 30D | ||||||||||||||

Temperature Range (℃) | Storage | -40~+60 | |||||||||||||

Installation | -20~+60 | ||||||||||||||

Operation | -40~+70 | ||||||||||||||

5. G.652D Optical characteristics:

Items | Content | Value |

Attenuation | @1310nm | ≤0.35dB/km |

@1550nm | ≤0.21dB/km | |

Dispersion | @1288nm~1339nm | ≤3.5ps/(nm·km) |

@1550nm | ≤18ps/(nm·km) | |

@1625nm | ≤22ps/(nm·km) | |

Zero-Dispersion wavelength | 1300nm~1324nm | |

Zero-Dispersion slope | ≤0.092ps/(nm2·km) | |

Mode field diameter (MFD) | @1310nm | 9.2±0.4μm |

@1550nm | 10.4±0.8μm | |

Cable cutoff wavelength λcc(nm) | ≤1260nm | |

Micro bending Attenuation | @1550nm (1turns;Φ32mm) | ≤0.05dB |

@1550nm (100turns;Φ60mm) | ≤0.05dB | |

Link polarization dispersion (PMDQ) | ≤0.1ps/km1/2 | |

Geometrical characteristics | ||

Cladding diameter | 125±1.0μm | |

Cladding non-circularity | ≤1% | |

Core/cladding concentricity error | ≤0.6μm | |

Fiber diameter with coating (uncolored) | 245±7μm | |

Cladding/coating concentricity error | ≤12.0μm | |

6. Color Code:

The individual fiber and loose tubes shall accordance with standard TIA/EIA-598-A and the color code as below.

3.1. Fiber color code in per tube

No. | 1 | 2 | 3 | 4 | 5 | 6 |

Color | Blue | Orange | Green | Brown | Grey | White |

No. | 7 | 8 | 9 | 10 | 11 | 12 |

Color | Red | Black | Yellow | Purple | Pink | Turquoise |

3.2. Loose tube (LT) color code

No. | 1 | 2 | 3 | 4 | 5 | 6 |

Color | Blue | Orange | Green | Brown | Grey | White |

No. | 7 | 8 | 9 | 10 | 11 | 12 |

Color | Red | Black | Yellow | Purple | Pink | Turquoise |

No. | 13 | 14 | 15 | |||

Color | Purple | Pink | Turquoise | |||

Fillier rod is uncolored (natural)

Categories

Contact Us

- +86-570-7669058

- 86 15264275519

- sales@neetuocommunication.com

- 8615264275519

- 8615264275519