Micro Drop Cable

Micro Drop Cable

1.General Description

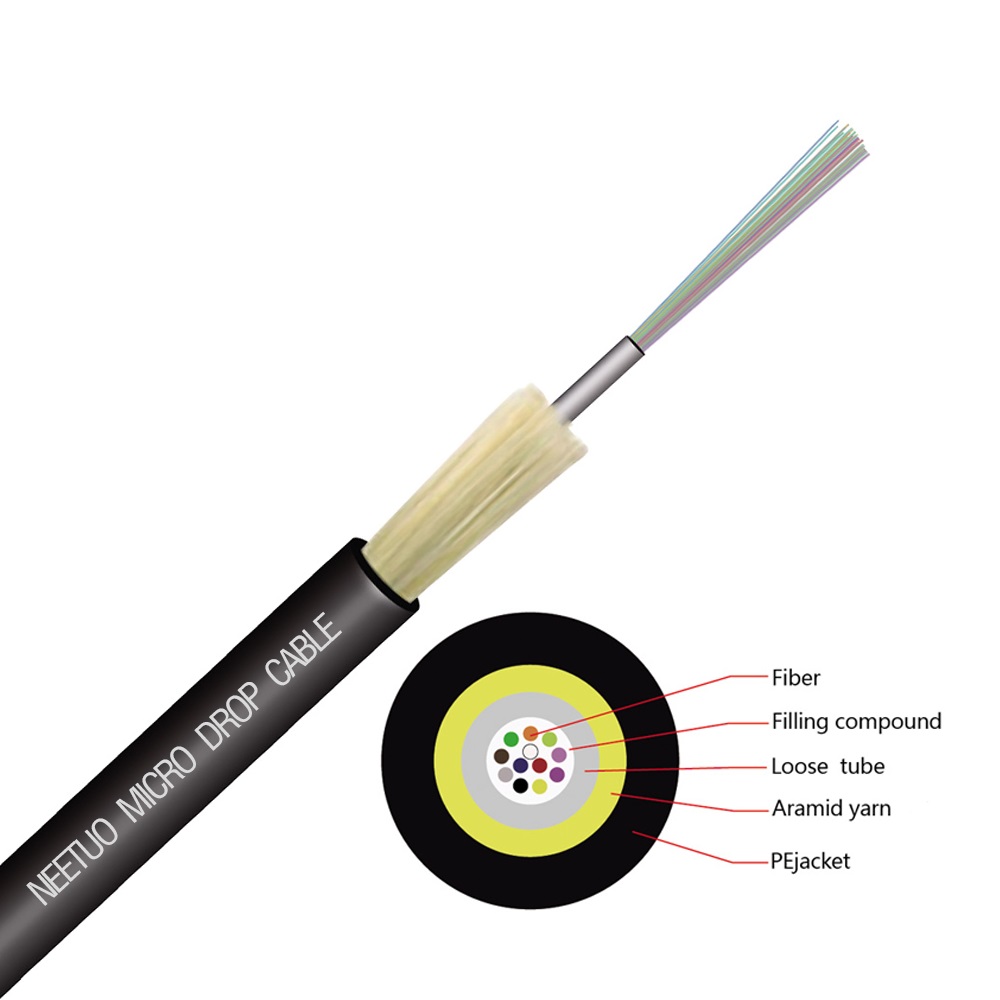

1.1 ,The fibre optic cable is a totally non-metallic structure and immune to any RF interference. The central tube is filled with thixotropic jell which allows for excellent sustained reliability over a wide temperature range, and is engineered to ensure the optical fibres remain stress free over the designated temperature range. The aramid yarn increase the tensil strength as well as for resistance to moisture ingress. The HDPE(High Density Polyethylene) sheath is UV stabilised for outdoor applications.

1.2, This cable is designed for outdoor aerial installation,or installation into micro duct. The span is up to 50m in aerial installation.

1.3, This cable has mature and stable production engineering, strict requirements of quality control, scheduled validation product performance to ensure the product reliability., the cable has up to life-span of 25 years.

2. Cable Structure and Physical Properties:

No. | Item | Parameters |

Optical Fiber | Type of fiber | G657A2 |

No. of Fiber | 1-12 | |

Color | Blue,Orange | |

Loosen tube | No. of tube | 1 |

Tube Diameter | 2.4mm | |

Sheath | Material | HDPE |

Thickness | 0.6mm | |

Cable Diameter(nominal) | 3.8mm | |

Cable Weight(nominal) | 12kg/km | |

MAX installation load( ≤ 0.25% fibre strain) | 144N | |

Minimum bend radius (long term/short term ) | 30/12mm | |

Crush Resistance (via 100mm plates) | 650N | |

Torsion | 10 Cycles 180°apart | |

Repeated Bending | 35 Cycles R=20xD | |

Temperature Performance | -10°C to +70°C | |

Water penetration (3m cable, 1m head of water) | No leakage | |

Drip test (300 mm sample of loose tube @ 80˚C) | No leakage | |

3.Optical Characteristics of G657A2:

Items | Content | Value |

Attenuation Coefficient | @1310nm | ≤0.36dB/km |

@1550nm | ≤0.21dB/km | |

Mode field diameter (MFD) | @1310nm | 8.6±0.4μm |

@1550nm | 9.6±0.4μm | |

Cable cutoff wavelength λcc(nm) | ≤1260nm | |

Micro bending lose(1 turn,7.5mm radius) | @1550nm | ≤0.5dB |

@1625nm | ≤1.0dB | |

Geometrical characteristics | ||

Cladding diameter | 125±0.7μm | |

Cladding non-circularity | ≤1% | |

Core concentricity error | ≤0.5μm | |

Fiber diameter with coating (uncolored) | 245±7μm | |

Cladding/coating concentricity error | ≤12.0μm | |

Proof stress level | ≥100kpsi | |

Categories

Contact Us

- +86-570-7669058

- 86 15264275519

- sales@neetuocommunication.com

- 8615264275519

- 8615264275519